Born of entrepreneurial spirit in 1961, BANCO Products INDIA Ltd, has today carved a niche for itself as a leader in the business of engine cooling and ceiling systems both for automotive and industrial applications.

BANCO combines the power of innovation and commitment to quality to create high-performance solutions for its customers.

The product range includes Engine Cylinder Head and Peripheral Gaskets, Heat Shields, and Industrial Gasket with a wide material range and sizes for demanding applications of sealing.

Materials include Multi-Layered Steel (MLS), Graphite Composite Gasket, Steel Fiber Composite Gasket, Compressed Fiber Joining Sheet Gasket, Rubber Cork Gasket, Rubber Pre- Coated Beaded Gasket, Edge Moulded Gasket, and Copper Gaskets.

Products

Copper is stronger than any composite head gasket yet it is still available does it confirms to the standards of sealing surfaces. The strength malleability combination is a unique attribute or the selling point of copper as a head gasket material over other materials. The copper gaskets available at Banco are copper sealing gaskets and copper pressed gaskets. They are used with flanges, automotive engines/ non-automotive applications and multiple engineering applications.

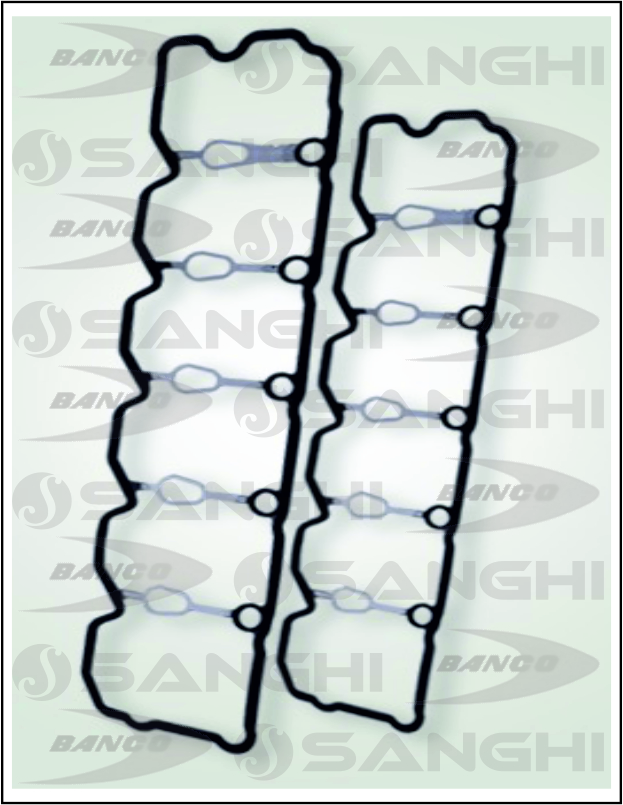

It is a unique combination of a fiber reinforced elastomeric beaded coating. The raised elastomeric beads provide high unit pressure and superior ceiling on narrow flanges. For several applications, the heat sensitive beaded coating provides a positive seal once the engine starts functioning. The rubber pre-coated b gaskets are used in applications where critical ceiling is a must.

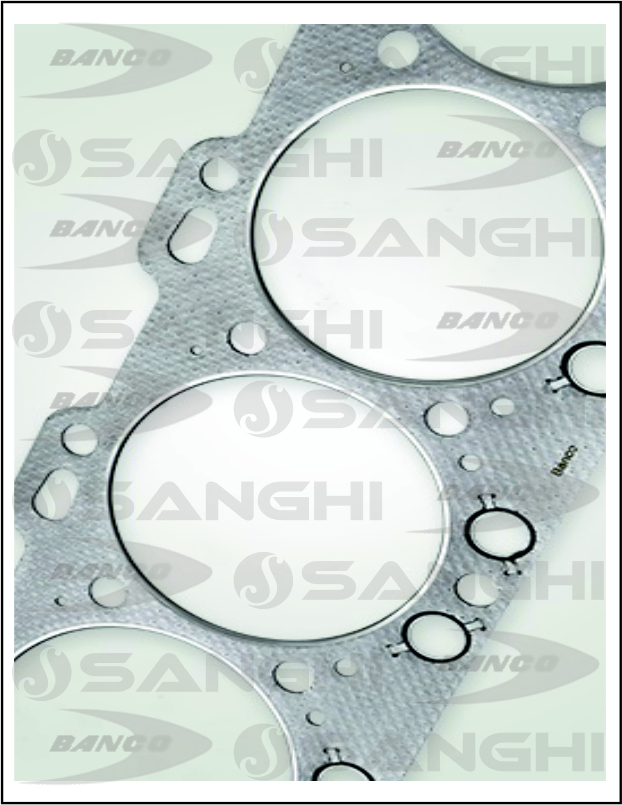

Steel Fiber Composite Gaskets are combined with inserted Steel fibre mesh. This composite is strong and durable with the reinforcement of Steel fibre. The main feature of these gaskets include effective fluid seal-ability, improved load distribution, improved blowout resistance, high compatibility with additional sealing aids such as coatings eyelets, grommets, etc.

Multi-layer Steel cylinder head gaskets are the only type of gaskets that meet the high performance engine requirements. Multilayer Steel head gaskets are made from thin spring stainless steel sheets. The outer sheets are coated with high-performance compounds for improved ceiling and embossed in critical areas. The sheets are held together on the perimeter by small brass rivets for installation.

High-strength graphite composite gaskets are stumped or punched gaskets made of metal sheets and flexible graphite sheets. The main feature of these gaskets include suitability for a wide range of applications such as high or low temperatures, high pressure resistance, corrosion resistance as well as radiation resistance.

They provide perfect ceiling performance with no overstrike requirement for the surface finish of flanges. Easy to install then a low pre tightening specific pressure.

Moulded aluminium gaskets are made from premium quality raw materials, thus are leak-proof and are able to withstand high compressive loads. The new generation edge moulded gaskets are ideal as cylinder head gaskets as they use aluminized Steel to resist high heat and vacuum. The silicone rubber sealing beads used for this gaskets are precision edge moulded to compensate for surface irregularities.

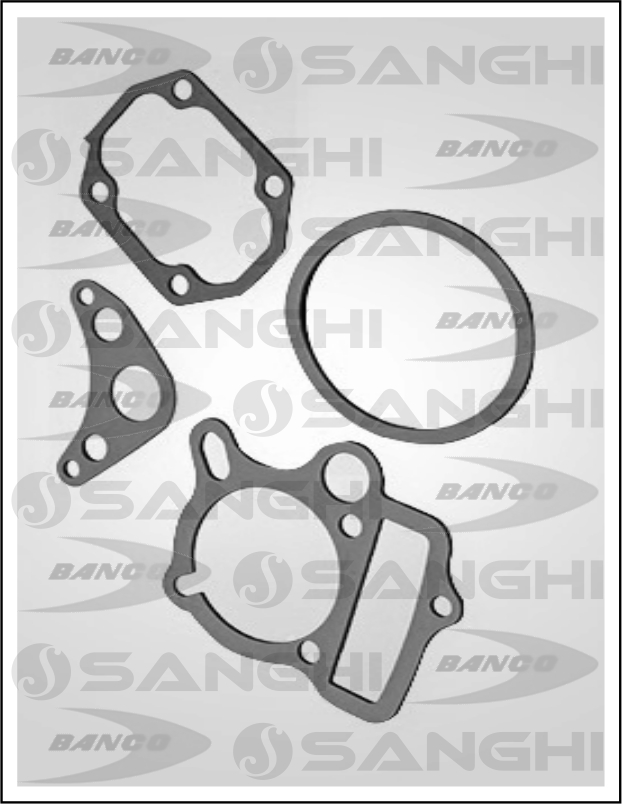

Compressed fibre jointing sheet / non-asbestos gaskets are die cut from compressed non-asbestos jointing sheets. These gasket seals are very effective to restrict the flow of material into the imperfections of joint contact faces.

These gaskets provide an unbroken barrier of the homogeneous structure through which no pathway exists for an escape of confined media.

BANCO has developed a wide variety suitable for various applications that meet National and international standards.

Compressed fibre jointing sheet or non-asbestos gaskets are mainly used in the high temperature and high pressure applications for equipment’s operating in saturated vapour / Super-hot vapour, gas, air, ammonia / alkali and inert gases as well as other mediums.